BABY CRIB

This crib was designed using Solidworks while I was attending Seattle University. The inspiration for this project was my wife being pregnant with our first daughter. I wanted to make her something special and one-of-a-kind.

It took me about four months to design this crib complete with drawings, materials list, and 1:1 templates for the more complicated curvatures. I began building the shop jigs and templates over spring break 2014. At this point I began to think that maybe I had taken on a project that was unrealistic given my school schedule and other time commitments. It took me about 12 hours in the shop and one quote for my lumber order to realize that this project would not become a physical reality before my daughter was born.

Since time is not a luxury I can foresee having in abundance for the next couple of decades, I can now only hope that I will be able to build this in retirement for my grandchildren. I would also love to provide the plans for this build to anyone who has an interest.

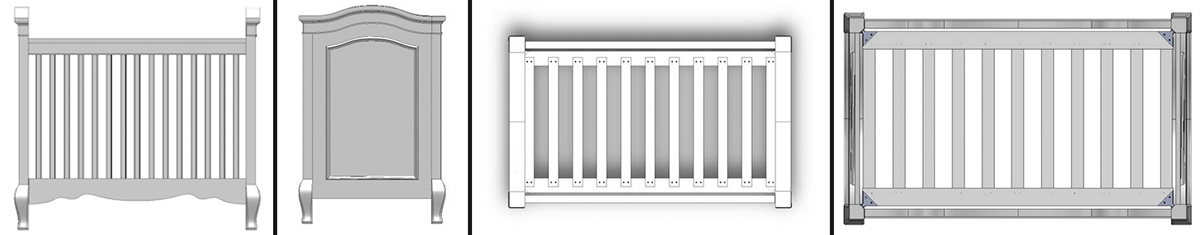

Views: Side | Front/Back | Top | Bottom

Design Considerations:

My Design Envelope...

- Hardwood construction

- Should support around 200 pounds (baby + parent)

- No gaps larger than 2 inches

- No Sharp Edges (bad for babies)

- No Sharp Edges (bad for babies)

- Adjustable mattress heights

- Baby cribs are subject to Federal regulations.

- ASTM standard = $72

- Tape Measure + Notepad + Target = $0

- Tape Measure + Notepad + Target = $0

I did not use a Federally recognized standard to design this crib.

Above: Bevel and Bracket Detail | Apron Curve | Headboard Curve

Overcoming Challenges:

I wanted a panel-in-frame look on both sides of the

headboards, but this left a sharp corner on the inside of

the crib. To maintain the integrity of the design and not

have any out-of-place offsets, I was forced to find a way

around this problem.

- The inside corner of each post was beveled at 45 degree so there were no sharp corners inside the crib.

- I used the beveled edge to house the bolt sockets for the adjustable mattress support assembly.

- The attachment hardware was custom designed to accommodate this specific situation.

Another essential design feature was the use of curves.

I wanted to strike a balance between simple and elegant.

After seeing the final design there are definitely things

that could have been simpler, but I enjoy woodworking.

Each of the elements represent a different skill that I was

looking to practice through this build. I spent a considerable

amount of time refining the curved shapes in Solidworks,

and I wanted an accurate translation of those curves to the

final piece.

- 1:1 templates were printed for the headboard and apron curves

- I printed the templates at my local print shop directly from a PDF drawing generated by Solidworks

- Recent experience has taught me that Adobe Illustrator is much easier for printing templates

- Paper templates can be glued directly to 1/4'' MDF to make routing templates for the final pieces

I wanted a panel-in-frame look on both sides of the

headboards, but this left a sharp corner on the inside of

the crib. To maintain the integrity of the design and not

have any out-of-place offsets, I was forced to find a way

around this problem.

- The inside corner of each post was beveled at 45 degree so there were no sharp corners inside the crib.

- I used the beveled edge to house the bolt sockets for the adjustable mattress support assembly.

- The attachment hardware was custom designed to accommodate this specific situation.

Another essential design feature was the use of curves.

I wanted to strike a balance between simple and elegant.

After seeing the final design there are definitely things

that could have been simpler, but I enjoy woodworking.

Each of the elements represent a different skill that I was

looking to practice through this build. I spent a considerable

amount of time refining the curved shapes in Solidworks,

and I wanted an accurate translation of those curves to the

final piece.

- 1:1 templates were printed for the headboard and apron curves

- I printed the templates at my local print shop directly from a PDF drawing generated by Solidworks

- Recent experience has taught me that Adobe Illustrator is much easier for printing templates

- Paper templates can be glued directly to 1/4'' MDF to make routing templates for the final pieces

Construction Mapping:

- Headboard panels are to be made from cabinet grade plywood and attached to each post using a stopped dado

- Headboard curves and moldings are to be shaped from solid wood using router templates

- Headboard curved tops are to be attached to the posts using mortise and tenon joints

- Top rail and apron boards are to be attached using commercially available mortise-in bed rail hardware

- Bars are to be attached to the top rail and apron using mortise and tenon joints

- The mattress support assembly is to be assembled using half-lap joints and screws

- The custom mattress support hardware is to be made from mild steel and should be attached using screws

- The final piece is to be finished using non-toxic products

This crib is designed to be built using wood products, and

all of the joints are intended to be set using wood glue

and clamping pressure. I had eastern maple and 7 ply

plywood in mind when the design work was happening. In

reality, any non-toxic hardwood could be used to construct

this crib along with plywood headboards to match. I would

strongly suggest using plywood for this project because it is

a much more stable wood product than large solid-wood

panels.

If this crib is ever built, I would not be surprised if the craftsman makes artistic changes to this design. All of the best planning and designing on a screen should not be assumed to be superior to the insight of the craftsman who brings a vision to life.

Thank you for viewing my project.

Thank you for viewing my project.